|

Magnetic filter holder simplifies clean-up and degassing of mobile phase solvents and other solutions

- Versatile design. Fits most HPLC bottles, flasks, and containers, and eliminates the added steps of washing flasks and transferring mobile phase solvent from flask to reservoir.

- Draws directly from HPLC solvent bottle. Less likely to spill aggressive solvents than glass funnels or disposable cups.

- Durable plastic construction. Less likely to break than glass funnels, assemblies, or pick-up adapters.

- Patented magnetic seal is reliable and leak proof. Eliminates the possibility of membrane shifting or tearing which can occur with aluminum clamps or threaded holders.

- Reusable, chemically resistant polypropylene construction. Resistant to common HPLC mobile phase solvents such as methanol, acetonitrile, and tetrahydrofuran

- Remove contaminating particulate from mobile phase or other solutions.

- De-gas mobile phase solvents and solutions.

- Eliminate pour-and-wait filtration.

- Remove microbial growth every 24 hours from aqueous buffer mobile phases

Materials of Construction

Upper Housing, Housing Base: Polypropylene

Feedline Tubing: Ultra chemical-resistant Tygon*, 4.8 mm (3/16 in.) ID

Thumb Clamp: Celcon*

Feedline Sinker: PTFE

Vacuum Port Adapter, Membrane Seal Gasket, and Seal Gasket: Polyethylene

Effective Filtration Area

10.2 cm2

Filter Size

Accepts 47 mm filter

Inlet/Outlet Connections

Tapered inlet accepts 3.2-6.4 mm (1/8-1/4 in.) ID tubing; outlet seals to bottles with openings 17.8 mm (0.7 in.) ID to 48.3 mm (1.9 in.) OD

Vacuum Port Adapter

4.8-7.9 mm (3/16 - 5/16 in.) tapered hose barb

Maximum Vacuum

63.5 cm Hg (25 in. Hg)

Operating Temperature

Ambient; not to exceed 38° C (100° F); not autoclavable

How To Use

|

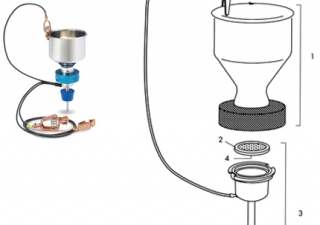

1. Place base on the receiving vessel with gasket seal seated on the rim of the vessel.* Then, place the membrane on the clean, dry filter support.

|

|

2. Attach inlet feedline tubing to the tapered inlet on the upper housing. Place upper housing onto housing base to securely seal the membrane. |

|

3. While holding filter housing assembly on receiving vessel, attach vacuum tubing from vacuum source to the vacuum port adapter located on the side of the housing base. |

|

4. Place vacuum feedline into solvent to be filtered. Be sure sinker is located well below the surface of the solvent, preferably on the bottom of the vessel. Place the thumb clamp just above the solvent bottle andclose it. |

|

5. Apply vacuum while holding the SolVac filter housing, applying even pressure to both sides, onto the receiving vessel until full vacuum is drawn. When the required vacuum is achieved and the system is "charged", open the thumb clamp to start the filtration. Continue to filter until all of the solvent is drawn through or the receiving vessel is full.

NOTE: To stop the filtration at any time, close the thumb clamp. After closing the thumb clamp, it is possible to change the reservoir vessel.

|

| * Always use a safety-coated receiving vessel that is < 4 L and rated for vacuum applications. Failure to do so may result in implosion of the receiving vessel and potential injury to the user. |

Recommendations for Optimum Performance

- Always begin filtration using a dry membrane and a clean dry support base to prevent airlock which can decrease or prevent liquid flow.

PTFE and Supported Membranes. Certain membranes such as supported membranes and fibrous media (e.g. PTFE and glass fiber) may not seal well in the SolVac filter holder due to the rigidity of the membrane or media surface. This may result in reduced flow rate. To correct this occurrence, place a membrane seal gasket on top of the membrane prior to final assembly of the filter holder.Make sure that you save these gaskets once you are done with your filtration so that you can use them in the future.

Hydrophilic Membranes. Once hydrophilic membranes are wetted with an aqueous fluid they do not allow air to pass through them. Because of this, it is critical that the PTFE sinker is on the bottom of the reservoir you are filtering from to minimize the potential to draw air into the filter holder prior to completing filtration.

- Always be sure sinker and feedline remain below the surface of the solvent to prevent air from getting into the feedline and creating an airlock.

- Use a receiving vessel that is of equal or greater volume than the vessel containing the mobile phase solvent to be filtered. Always monitor the filtration process to prevent overflow.

- For optimum performance use vacuum pressure of 51-64 cm (20-25 in.)

- Conventional lab vacuum pumps such as Pall Life Sciences' vacuum pumps (115 and 230 V) are ideal for use with the SolVac filter holder. We recommend the use of a Vacushield™ vent device to protect valves and pump components from damage

|